Pan Style Mini-Brake

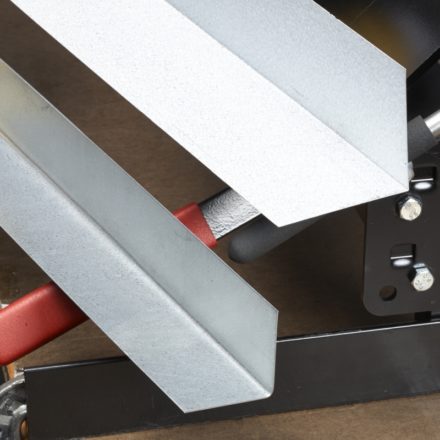

The MB48B “Pan Style” Mini-Brake is designed to fabricate drip pans and register boxes, as well as complex corners for flashing and fascia, on the job. At just under 100 pounds (45 kg), it is carried comfortably by two people, or quickly separated into anvil and table components for one-person transport. The MB48B operates on a workbench, tailgate, or optional legs to produce 135° bends in 22-gauge (0.86 mm) galvanized steel at a maximum 48-inch (1.2 m) width. A 5/16-inch (7.9 mm) plate-steel table apron and anvil frame, with adjustable set-back and strengthening ribs, ensures a uniform bend. Cam-over-center clamps keep the anvil secure in any position for safe operation. For making pans and boxes, the full anvil is comprised of 16 movable, plate-steel fingers: Five 2-inch (50.8 mm); Six 3-inch (76.2 mm); and Five 4-inch (101.6 mm) fingers to create a maximum 48-inch (1.2 m) bending width. Minimum bending width is limited to the 2-inch (50.8 mm) finger width. Anvil clearance allows a range of flange-height dimensions from 1/2 to 3-inches (12.7-76.2 mm). No fixed throat depth also makes the MB48B ideal for fabricating large ductwork, flashing and fascia components on the job.

FAQs

Q: How do I adjust the MB48B?

A: See the instructions for the brake: SL16086B_Pan Style Mini-Brake 5 language Instructions.indd (malcotools.com)

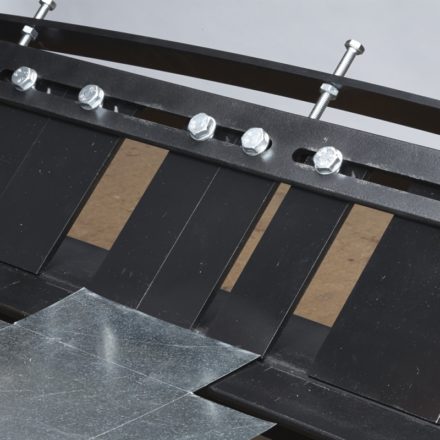

Anvil Position Adjustment (Setback): Differences in the material being formed (such as thickness and temper) can affect the sharpness of the bend. The MB48B anvil position can be adjusted for these differences. Setback is the distance from the forward edge of the finger to the pivot edge of the apron. Typical setback is 1-2 times the material thickness. (A) Allow fingers to rest on table (not clamped). (B) Loosen anvil position plate bolts, adjust anvil position to desired location (C), and retighten bolts. Note: While adjusting setback, ensure the anvil is parallel to the apron or bend distortion may occur (D).

TENSIONING ADJUSTMENT: The MB48B comes equipped with an adjustable strengthening rib on the anvil. This rib is preset at the factory for optimal performance. Increased tension may be desired when consistently bending heavier materials. (A) When bending a full 48 in. (122 cm) width in 22-gauge (.89 mm) galvanized steel, a 3/4 in. (19 mm) depth is the shortest possible bend. In 28 ga. (.48 mm), a 1/2 in. (12.7 mm) depth is the shortest possible bend. In 22-gauge (.89 mm) galvanized steel, expect a 1/4 in. (6.35 mm) bend radius. In 28 ga. (.483 mm), expect a 1/8 in. (3.175 mm) bend radius. (B) While using an open-end wrench to keep each nut from turning, fine tune each of the 3 bolts shown (C) clockwise to increase the anvil tension. Turn counterclockwise to decrease the anvil tension. Best results are achieved with the anvil adjusted so that it is parallel with the entire width of the apron. IMPORTANT – As a precaution against over-adjusting your MB48B, use a marker to indicate the original factory settings on each of the adjustment bolts.